In the ever-evolving landscape of printing technologies, offset printing has held its ground as a reliable and high-quality method for mass production. Known for its efficiency and cost-effectiveness, offset printing is a go-to choice for high-volume print jobs such as newspapers, magazines, brochures, and packaging.

But how exactly does this centuries-old printing technique work? Let’s delve into the mechanics, materials, and principles that make offset printing a staple in the printing industry.

The Basic Principle: Offset Transfer

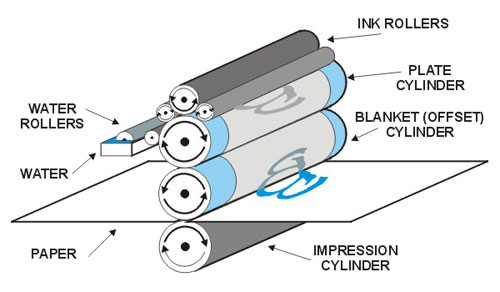

The term “offset” refers to the transfer of ink from a plate to a rubber blanket, and then finally onto the printing surface. Unlike direct printing methods, where ink is applied directly from the plate to the paper, the offset process involves this intermediate step. This ‘offset’ mechanism allows for a more accurate and consistent reproduction of images and text.

The Core Components

Printing Plates: In offset printing, the information to be printed is etched onto metal plates, usually made from aluminum. These plates are coated with a layer that holds onto ink in the areas that are meant to be printed, while repelling ink in the non-image areas.

Rubber Blanket: The rubber blanket is a key element in the process, acting as the intermediate surface that receives the inked image from the plate and transfers it onto the paper.

Rollers: The printing unit contains several rollers: ink rollers, water rollers, and impression rollers. These play crucial roles in distributing ink and moisture uniformly across the plate and rubber blanket.

Paper Feed: The paper feed system pulls individual sheets from a stack or a roll, guiding them through the printing unit and then onto the output tray.

The Printing Process: Step-by-Step

Preparation: Before the actual printing begins, the metal plates are prepared with the desired images or text. This is usually done using computer-to-plate (CTP) systems, which transfer digital data onto the plates.

Dampening: The plate first passes through the dampening unit, where water is applied to its surface. Because the plate is chemically treated, water adheres only to the non-image areas.

Inking: Next, the plate moves through the inking unit, where ink rollers distribute ink across its surface. The ink sticks only to the image areas, repelled by the water in the non-image sections.

Offset Transfer: The inked plate then makes contact with the rubber blanket, transferring the image onto it.

Impression: The paper is fed through the press and comes into contact with the rubber blanket. The inked image is transferred from the blanket onto the paper.

Drying and Finishing: The ink on the paper needs to dry before any additional processes like cutting, folding, or binding can occur. Some offset printers have built-in drying units for this purpose.

Advantages and Limitations

Advantages

High Quality: Offset printing offers exceptional image quality, with sharp and clean reproductions.

Cost-Effective: The unit cost goes down as the quantity increases, making it ideal for large print runs.

Versatility: Capable of printing on a wide variety of surfaces including paper, cardboard, and plastic.

Limitations

Setup Time: The preparation of plates can be time-consuming.

Not Ideal for Short Runs: Due to setup costs, offset printing may not be cost-effective for small quantities.

Offset printing has remained popular for good reasons: its versatility, high-quality output, and cost-effectiveness for large runs are hard to beat. As technologies continue to advance, offset printing too adapts, integrating more digital elements to streamline the process. However, the core principles have remained the same, standing the test of time and technology.

Whether you’re looking to print a high-quality magazine or mass-produce packaging, offset printing is a technique worth considering.

Technological Advancements: Merging Digital and Offset

While the principles of offset printing have remained largely unchanged, technological innovations have introduced digital elements to complement traditional methods. One significant development is the integration of Computer-to-Plate (CTP) systems, which have replaced older methods of plate production like Computer-to-Film (CTF).

With CTP, digital images are directly transferred to printing plates, reducing errors and speeding up the production process.

Hybrid Printing

Another emerging trend is hybrid printing, where digital and offset printing methods are combined in a single print job. This offers the best of both worlds: the cost-effectiveness of offset for high-volume elements, and the customization abilities of digital for variable data like addresses or personalized messages.

Environmental Considerations

As with any manufacturing process, offset printing has environmental implications. Traditional inks and solvents may contain volatile organic compounds (VOCs) which are harmful to both health and the environment.

However, the industry is adapting by developing vegetable-based inks and water-based coatings. Waste management has also improved, with many offset printing companies now recycling or repurposing the aluminum plates used in the process.

Troubleshooting Common Issues

Even with its proven reliability, offset printing is not without its challenges. Here are some common issues and how they are usually resolved:

Ghosting: Ghosting refers to the unintentional appearance of a faint image in areas where it shouldn’t be. This is often caused by an imbalance in the ink-water ratio, and can be corrected by adjusting the settings on the dampening and inking units.

Dot Gain: Dot gain occurs when printed dots are larger than intended, usually due to over-inking or paper absorption. The press operator can rectify this by reducing the ink flow or choosing a less absorbent paper stock.

Smudging: Smudging happens when freshly printed sheets come into contact with each other before the ink has dried. Adding drying accelerators or anti-set-off powders can mitigate this issue.

Future Outlook

The printing industry as a whole is undergoing a digital transformation. While digital printing technologies are improving rapidly, offering quicker setups and more customization, offset printing is not expected to disappear anytime soon. Rather, as the two technologies coalesce, we can expect to see even more efficient and versatile printing solutions that leverage the strengths of both methods.

Offset printing, with its rich history and proven mechanics, remains a cornerstone in the world of print production. From newspapers to packaging to high-end art reproductions, its reach is vast and its applications many.

The technology continues to evolve, incorporating digital advancements to stay relevant in an increasingly digital world. Despite its few limitations, the benefits it offers in terms of quality, cost-effectiveness, and versatility make it a viable choice for a wide range of printing needs.

Expert Tips for Maximizing Offset Printing

Color Management: A well-managed color workflow is essential for achieving high-quality prints. This includes calibrating monitors, standardizing color profiles, and performing periodic checks throughout the printing process. It’s a good practice to generate proofs before the full print run to ensure that the colors meet expectations.

Paper Selection: The type of paper or material used can greatly affect the final output. Thicker, less absorbent papers often yield sharper, more vibrant prints. Always consult with your print service provider about the most suitable paper stock for your particular project.

Prepress Checks: Before sending your designs for printing, always ensure that they meet the specifications laid down by the printer. This includes things like resolution, bleed, and crop marks. Proper prepress checks can save both time and money by avoiding last-minute corrections.

Quality vs. Speed: Striking a Balance

Offset printing is generally slower than digital printing due to the setup involved. However, once the machine is running, the speed can be quite fast, especially for long print runs. The key is to find the right balance between speed and quality, based on the specific requirements of your project.

Cost Factors

While offset printing is cost-effective for large volumes, several factors can influence the final cost. These include:

Plate creation: Unique plates are needed for each color in the design.

Paper: High-quality, specialized papers are generally more expensive.

Color: Full-color printing is more expensive than monochrome.

Finishing touches: Features like lamination, embossing, or special cuts add to the cost.

Understanding these factors can help you manage your budget more effectively.

A Time-Tested Technique with Modern Appeal

Offset printing stands as one of the most reliable, high-quality methods of print production available today. Its ability to efficiently produce large volumes of crisp, vibrant prints has cemented its place in the industry. While newer, quicker digital methods offer formidable competition, they often can’t match offset when it comes to quality and cost-efficiency for large runs.

By integrating new technologies and adapting to modern demands, offset printing is showing its resilience and adaptability. As long as there’s a need for high-quality, large-scale print jobs, offset printing will continue to be a technology that people turn to, from publishers and marketers to artists and manufacturers.

With a deep understanding of the process, components, and variables that go into offset printing, you can make informed decisions that yield exceptional results for your specific needs. Whether you are a seasoned designer, a business looking for large-scale printing solutions, or simply a curious individual, the fascinating world of offset printing has something to offer.